Professional Expertise and Quality under one roof

Already in 2002 the O-Ring-Test-Laboratory Richter was accredited for the first time. Since then the accreditation has been continuously supervised and is renewed in the officially required periods.

The term “accreditation” is derived from Latin and means “to give credit to.” An Accreditation is a more far-reaching safe-guarding instrument than a certification. It is a “third-party attestation related to a conformity assessment body conveying formal demonstration of its competence to carry out specific conformity assessment tasks.” (quoted from https://www.iso.org/obp/ui/#iso:std:iso-iec:17011:en chapter 3.1) Or to put it simply: A higher national authority checks if a laboratory has the know-how and the ability to apply and to perform the offered tests in accordance with the regulations.

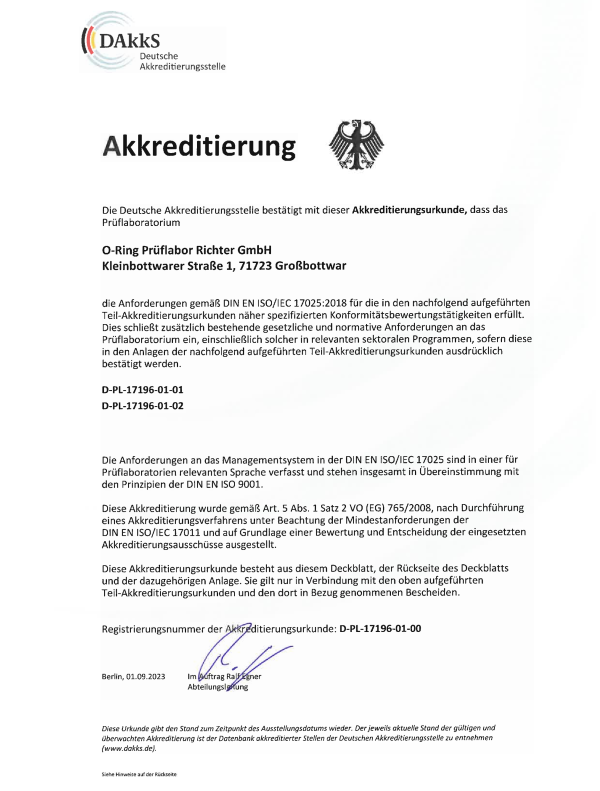

Accreditation

A test laboratory is accredited if it meets the requirements of DIN ISO/IEC 17025. This standard describes the requirements on the professional expertise and the QM-system of a test laboratory, is accepted globally and includes the QA-standard DIN EN ISO 9001:2008.

To undergo the procedure of an accreditation and to meet the set requirements in the process involves a high internal amount of work and organisation and demands an enormous professional expertise which the O-Ring-Test-Laboratory Richter has proved through its accreditation and demonstrates every day anew. A successful accreditation is a clear sign for and a definite affirmation of lived quality.

Due to an EU-regulation of 2010 the accreditations have to be carried out by one authority in every member state. In Germany this task is exercised by the “Deutsche Akkreditierungsstelle GmbH” (DakkS) (Germany’s National Accreditation Body) based in Berlin. The shareholders of this private limited company are at one third each the German Federal States, the Federal Republic of Germany, and the Federation of German Industries (BDI). Previous to the fusion of all national accreditation institutions in 2010, the “Deutsche Akkreditierungssystem Prüfwesen“ (DAP) (German Accreditation System for Testing) was responsible for our laboratory.

The scope of our accreditation covers mechanical/technological tests of seals, moulded components, and materials of elastomers. Overall the list of accredited tests includes 70 different test standards (ISO, DIN, VDA, ASTM-standards) and is valid until 13.11.2022. Please refer to the above-mentioned link to the website of the DakkS to see whether your requested test is accredited.

Of what benefit is this accreditation for you?

It is approved by the highest national authority

- that our testing methods are reliable concerning quality and safety

- that they are compliant with the respective laws and standards

- that we are a competent contact in the area of elastomer testing and our staff are professional experts in their field

- that in disputes (complaints, legal conflicts) you can refer to our independent test results without hesitation and these are accepted internationally

- that our test results can also be compared internationally with other accredited test laboratories

- that our testing technology is always at the latest state of the art, as our accreditation has to be renewed at regular intervals

How to differentiate a certification from an accreditation?

From your professional daily routine you certainly know the instrument of certification or respectively you know it better than the instrument of accreditation.

The word ‘certification’ is derived from Latin and can be paraphrased with the term ‘to secure something.’ By a certification it is guaranteed that e.g. a test laboratory complies with certain necessary quality requirements.

A certification is conducted by an independent certification authority (e.g. TÜV – German Association for Technical Inspection, DQS et al., and is limited in time. Most industrial enterprises today are certificated according to ISO 9001 (quality management) and ISO 14001 (environmental management). In the European and North American automotive industry certifications according to ISO/TS 16949 are standard. Generally speaking they are management systems which are supposed to guarantee that certain specified requirements for a product, a process, for staff or a system are met. Therefore the correctness of procedures is looked into first and foremost, not if their contents are technically correct or make sense in every particular case.

To put it simply you could say that a certification is a kind of pre-stage of an accreditation. The O-Ring-Test-Laboratory Richter is not certificated because we are qualified according to the further reaching quality instrument namely the accreditation.

Downloads

Accreditation certificates (German)

Show PDF / download

Attachment to accreditation certificate (German)

Show PDF / download

Test methods in the flexible scope of accreditation

Show PDF / download