In the O-Ring Prüflabor Richter, a workstation for qualified tightness testing of elastomer sealing systems is now available. This procedure must not be confused with the density test of rubber, a classic standard material characteristic.

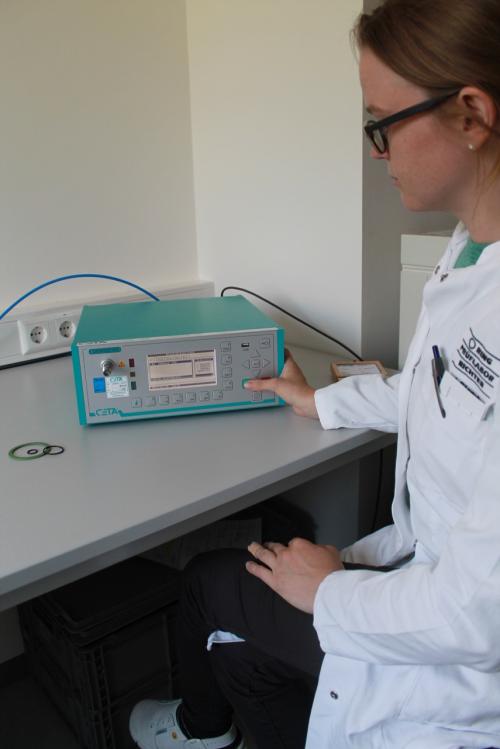

The used tightness testing device CETATEST 815 works according to the differential pressure method, which means that the pressures in the test part volume are compared with an absolutely tight reference volume. The device has a display resolution of 1 Pa, but internally it works with an effective resolution of 0.01 Pa. The test medium is compressed air, which is dried in advance and cleaned by an intermediate filter in order to exclude unwanted interfering factors. The measured pressure changes are then automatically converted into the known leakage rates (e.g. ml/min or ml/h).

With our new test method, we are able to test more rigid specimens, such as classic elastomer seals, but not very flexible materials, such as foils. The seals to be tested are installed in individually manufactured test chambers and exposed to a variable overpressure from 20 mbar to 1000 mbar. The test pressure must be selected according to the respective test task. The device measures the pressure drop or the leakage rate. Depending on customer requirements, aging (e.g. due to hot air or media) in unpressurized condition at the seals is also possible to obtain conclusions about the tightness after such degenerative processes.

For further information please contact us, we would be pleased to assist you with any inquiries.