Identity Test

Hardness and density are fast and easily ascertained. Therefore, they are ideal for incoming goods inspection and testing.

moreHardness Test

The hardness test is probably the most applied and most common test method in the elastomer industry.

moreCompression Set

This test indicates how much a seal or a material loses its recovery behaviour after predefined thermal stress.

moreCompression Set at low temperatures

The crucial test for sealing materials at low temperatures: what remains of the recovery behaviour.

moreTension Set

The practical benefit of this test entails ascertaining the degree of cross linking of finished parts where a compression set test is not applicable.

moreTensile Tests

This test is not only about physical material properties, it can reveal a lot more.

moreImmersion Tests

We conduct durability tests in oil, fuels, coolants, refrigerants, superheated steam and many more media.

moreHeat Ageing

The thermal resistance of an elastomer ranks among its most important characteristics. However, there are different possibilities to check it.

moreOzone Resistance

Many elastomers may become cracked even under normal environmental ozone concentrations.

moreThermogravimetric Analyses

The thermogravimetric analysis is probably the most often applied analytical test for elastomer materials.

moreDimensional Inspection

That seals can be easily mounted and can function properly is closely related to their dimensional stability.

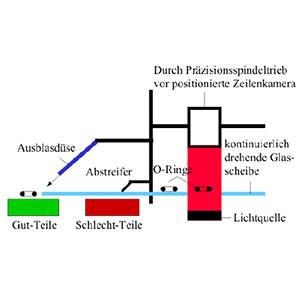

moreSortation according to given Tolerances

If the sealing measurements are not right and a remedy is needed urgently then there is only one thing to do – to sort once again.

moreVisual Inspection

Due to the difficult processability the visual inspection constitutes an important safeguard.

moreStress Relaxation in Compression

During this test it is measured continually how the sealing force changes under the influence of temperature, medium and testing time.

moreTear Strength

Important test for dynamic seals and there can be enormous differences within a material group.

moreInfrared Spectroscopy

In the final analysis this method shows the natural vibrations of organic molecules whereby, particularly with elastomers, functional groups can be detected.

moreDifferential Scanning Calorimetry (DSC)

This calorimetric test detects the thermodynamic glass transition of elastomers, i.e. the transition from energy elasticity to entropy elasticity.

moreRebound Resilience

Where elastomers are use as bumpers their self-heating caused by destroyed energy should stay as low as possible.

moreMeasurement of Electrical Properties of Elastomers

To avoid electrostatic charge or electrochemical degradation

morePyrolysis GC-MS

The analysis method with the highest resolution to receive indications which ingredients elastomer samples have. For this a 1 mg sample is already sufficient.

moreFailure Analysis

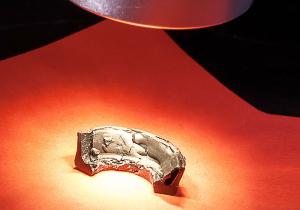

For the O-Ring Prueflabor Richter the failure analysis of elastomeric seals is one of its core competences.

more