Differential Scanning Calorimetry

Test Standards: VDA 675116, DIN 53 765, ASTM D 3418

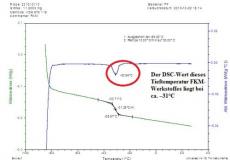

The measurement principle of this test method is that the heat flow which is needed for the heating of specimens can be ascertained very accurately and in this way phase transformations, enthalpies of fusion and chemical reactions within the specimen can be detected. This applies for many different substances; the most common application of this method with rubber materials in practice is that with it the phase transition at low temperatures from energy elasticity to entropy elasticity (also referred to as rubber elasticity) can be determined. The advantage of this method is that it can be applied on finished parts very well and that its analysis is also employed to characterise other substances, especially thermoplastic materials, although in this case rather at high than at low temperatures. Therefore the method is very widespread by now. The disadvantage of this method is that from an application-specific point of view the result cannot be assessed as well as for example the TR-10-value (see test methods). On the whole there certainly is a correlation with the TR-10 value which is influenced by the polymer and the structure of the formula, though. The DSC-values of FKM-materials can be assessed particularly well because based on experience they correspond 1:1 with the TR10-value within the limits of the typical uncertainty of measurement.

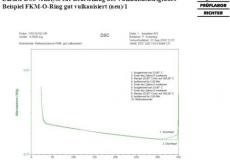

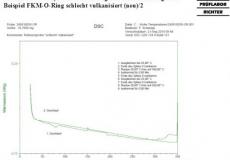

In addition to the representation of the phase transition of elastomers at low temperatures, the DSC-test at high temperatures can show by an exothermic reaction whether there are still curing agents in an O-ring or seal which would be strong evidence for an under-cure. With an ideally cured rubber sample there is no difference in progression between first and second heating from 23 to 300°C, see figure 2. Whereas looking at the sample with the poor compression set, figure 3, a significant difference can be seen between the first and second run, especially an exothermic reaction at approx. 150 °C during the first run. Therefore, if there is an exothermic reaction in an O-ring which has failed due to permanent deformation this is evidence for unsatisfactory curing. However, the converse is not obligatory because application temperatures could have already caused a post cure and in this way could have neutralised the curing agent which has not yet been used up.

Expert Knowledge on Physical Analytical Test Methods:

Show PDF/download